Hot Work Permits: A Practical Guide to Safer Operations

Understanding the role of permit-to-work systems in managing high-risk activities safely

Introduction

In the previous instalments of our hot work series, we identified some frameworks that contribute to developing a safe system of work. In this article, we will cover another system that aids the development of safe systems of work: permit-to-work systems.

What is a permit-to-work system?

A permit-to-work (PTW) system is an administrative system typically used for high-risk work activities. It aims to ensure that work is properly planned, managed, monitored, and executed without risks to health and safety.

Why should a permit-to-work system be used for hot work?

Hot work is a high-risk activity, mainly due to the risk of fire and explosion. In addition to the risk of fire and explosion, some hot work activities, such as welding and soldering, are specialist activities, making it imperative that competent operatives carry out these activities.

Implementing a permit-to-work system ensures that activities are properly planned, managed, monitored, and carried out by competent and authorised operatives.

Benefits of PTW systems:

Permit systems ensure that hazards and risks are identified and appropriate controls are implemented before work commences.

Permits provide clear evidence of who is authorised to complete the work and ensure unauthorised work is prevented.

Permits help improve coordination and communication among the workforce by clearly documenting roles, responsibilities, and safety arrangements.

Permits offer clear information on planning, execution, and supervision. They also provide a paper trail, which supports investigation and reporting and simplifies identifying areas for improvement.

Permits facilitate emergency preparedness, ensuring appropriate emergency responses are planned.

What should be contained in a permit?

A permit contains four primary sections:

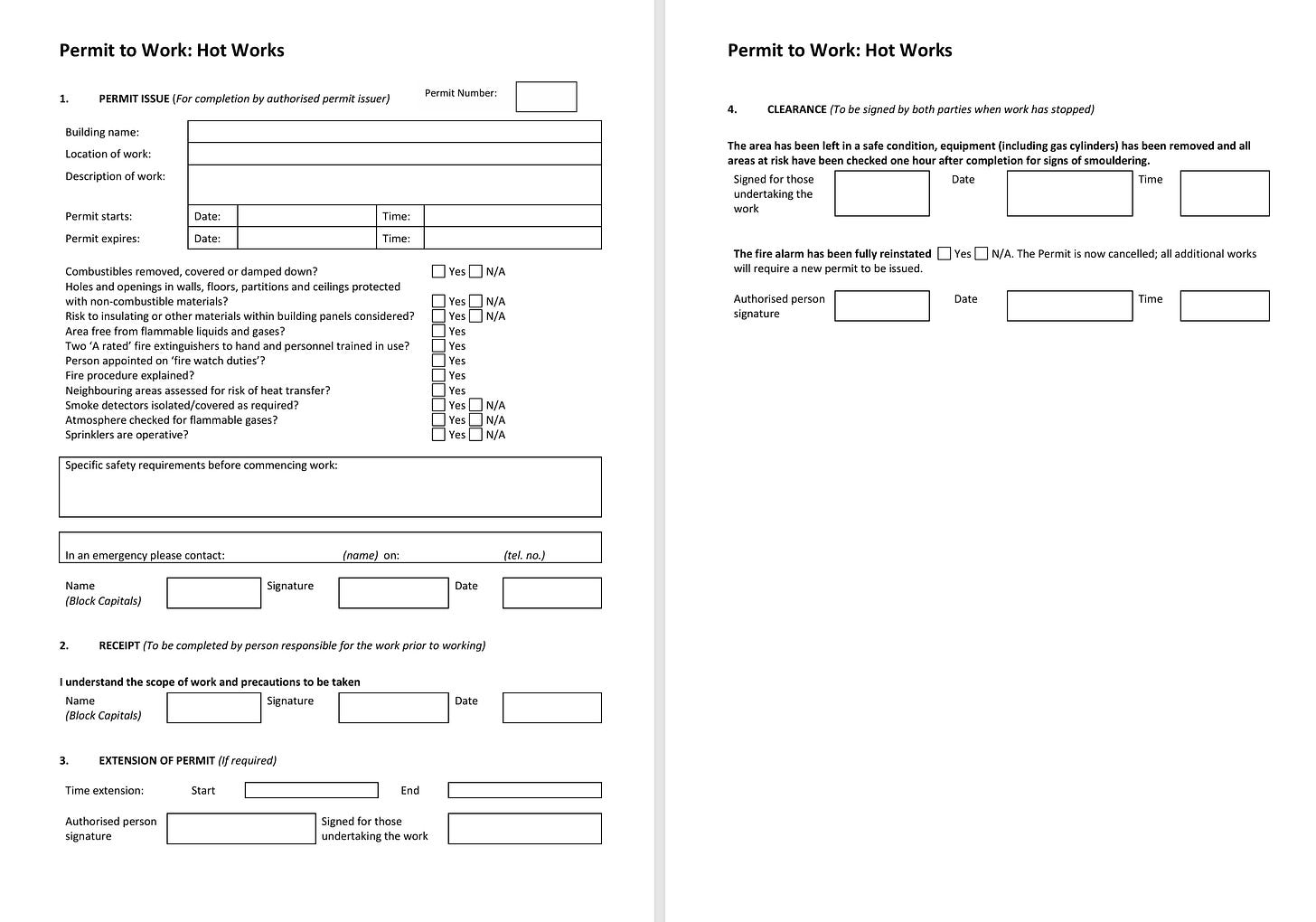

1. Issue: The permit issuer (typically a manager) is responsible for completing the permit's issue component. They must be competent to do so, meaning they understand the work activity, hazards, risks, and necessary controls. The issue should contain the following information:

Permit reference number

Name and position of issuer

Location of work

Description of the work planned

The names of the individuals authorised to complete the work

Date and time of issue and the duration the permit is valid for (typically one working day)

Hazards and risks associated with the work and the proposed control measures

Signature of the permit issuer

2. Receipt: The receipt component is completed by the operative(s) carrying out the work. They must sign the permit to confirm they understand the hazards, risks, and controls with which they are required to comply. The receipt should contain the following information:

Full names of operative(s) carrying out the work spelt in capitals

Signature of the operative(s) carrying out the work

Date and time

3. Clearance: The clearance component should contain the signatures of the operative(s) who carried out the work. The signature confirms that the job is complete, the area has been left safe, and everyday activities can continue.

4. Cancellation: The permit issuer signs the cancellation section to confirm that the permit is cancelled and that no further work may be carried out under its authority.

When implementing a permit-to-work system, it’s essential to remember that it will only be effective if reviewed by a competent person and if the work activity is continuously supervised to ensure ongoing compliance with the permit conditions.

Image description: The image above illustrates a hot works permit.

Recap

Permit-to-work (PTW) systems are vital for managing high-risk activities. They ensure tasks are properly planned so they may be executed safely.

PTW systems are essential for hot work due to risks such as fire and explosion; permits ensure that only authorised personnel may carry out the work.

For a PTW to be effective, the permit conditions must always be complied with, meaning continuous supervision by the permit issuer is essential.