Building a Safer Workplace: Applying the Hierarchy of Controls to Hot Work

A guide to practical safety measures and prevention principles for high-risk activities

Introduction

Part 3 of this series covered the importance of risk assessments and their role in developing a safe system of work. As we discovered, control measures must be selected in accordance with the hierarchy of controls and the principles of prevention set out in The Management of Health and Safety at Work Regulations (MHSWR 1999). In this article, we will look at both frameworks, how they can be applied, and some examples of actionable measures that can be used to control the risks associated with hot work.

Principles of Prevention

Outlined in the MHSWR 1999, the principles of prevention are designed to guide the development of effective health and safety arrangements. These principles help identify and implement measures to mitigate workplace risks. The principles of prevention are as follows:

Eliminate the risk: This can be achieved by doing the work differently, such as using flame-free joining methods to eliminate the need for hot work entirely.

Combat the risk at source: Address the risk directly at its origin, e.g., using water suppression for cutting activities to prevent dust from becoming airborne.

Adapt the work to the individual: Consult with the individuals involved when making decisions regarding workplace design, selection of PPE, work equipment, and safety procedures.

Leverage technology: Use technology and innovations that help to make work activities safer, such as equipment with built-in dust extraction systems.

Develop a safe system of work (SSOW): Create a formal plan that details how risks will be mitigated or prevented, how tasks will be conducted, and the condition of the work environment. The company's health and safety policy should be based on this plan. NB: H&S policies are a legal requirement under section 2(3) of The Health and Safety at Work (HSW) Act 1974.

Prioritise collective control measures: Measures that protect the entire workforce should always be prioritised above measures that only protect the individual. For example, respiratory protective equipment (RPE) only protects the wearer, whereas ventilation systems protect everyone nearby.

Provide suitable information, instruction, and training: All workers (whether employed or self-employed) should clearly understand their responsibilities regarding health and safety at work.

Foster a positive health and safety culture: Encourage a workplace culture prioritising health and safety above profit and time efficiency. A company's leadership and management set the standard for the overall culture.

For a deeper understanding of how company culture impacts health and safety, read our article “Beyond Regulations: The Crucial Role of Company Culture in Construction Health and Safety.”

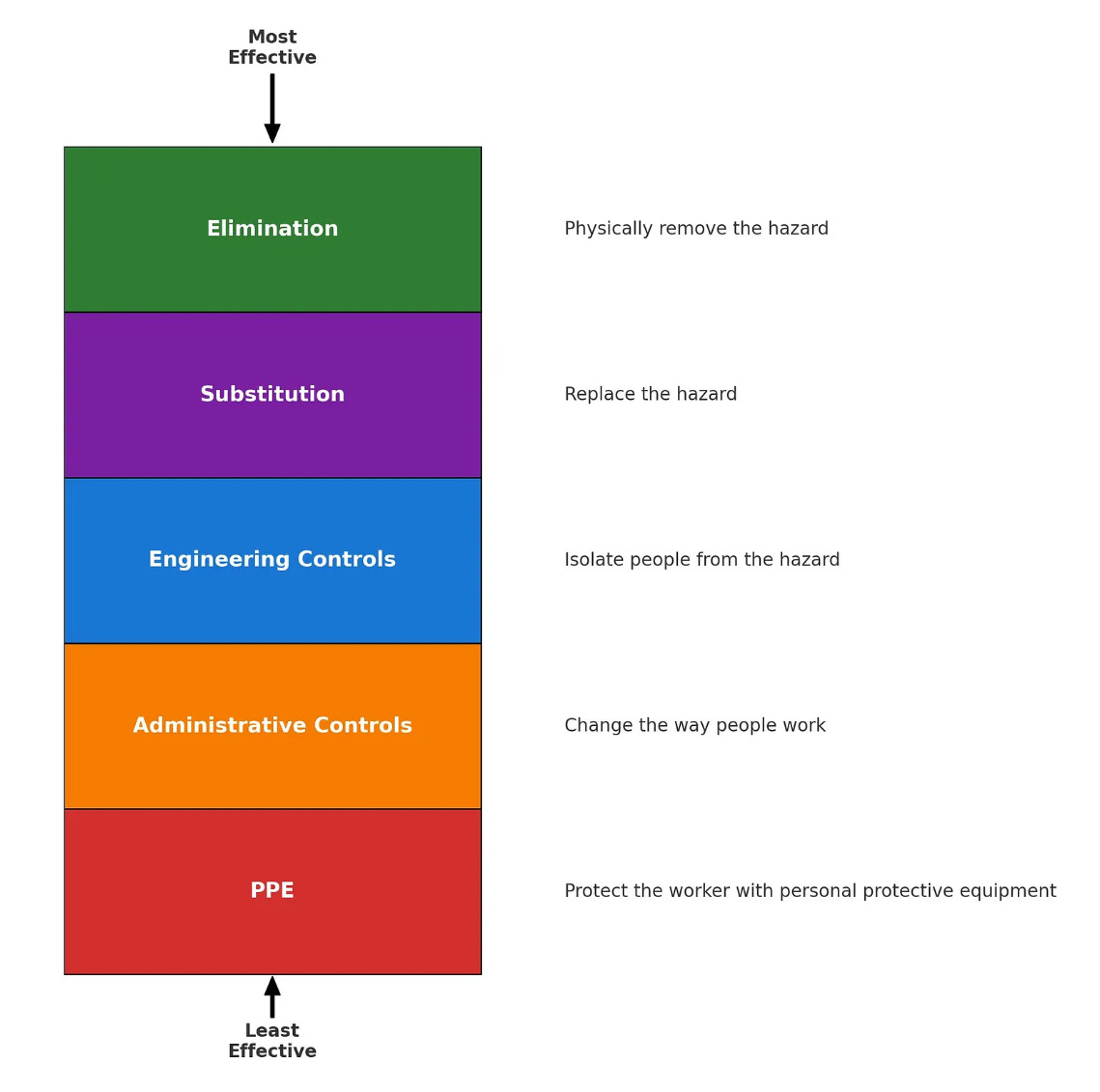

What is the hierarchy of controls?

The hierarchy of controls is a framework used for determining which control measures are most effective in removing or reducing hazards. The hierarchy is structured starting with the most effective control measures down to the least effective measures:

How can the hierarchy of controls be applied to hot work?

1. Elimination

Elimination is to remove the hazard itself. An example of this control would be using pre-cut or prefabricated materials to eliminate the need for hot work entirely.

2. Substitution

When elimination is not reasonably practicable, substitution for hot work may involve:

Using flame-free joining methods such as adhesive bonding or mechanical fastening (use of screws, nuts and bolts to join components).

Use of cold-cutting machinery such as band saws, diamond wire saws or abrasive water jet cutting.

Using push-fit fixings instead of metal pipes to remove the need for soldering.

3. Engineering controls

The hazard is changed at its source by modifying the work activity or area to reduce the risk. Controls for hot work may include:

Use of water suppression for cutting activities.

Use of on-tool extraction systems.

Use of local exhaust ventilation (LEV) systems.

Use of welding curtains/screens.

4. Administrative controls

Organising the work in a manner that reduces the risks, in other words, developing a safe system of work (SSOW). Controls may involve:

Implementing a permit-to-work system.

Appointing a competent ‘fire watcher’.

Establishing arrangements for monitoring, supervision, inspection and housekeeping.

Organising the provision of information, instruction and training.

Implementing site security arrangements, e.g. perimeter fencing and safety signage.

Establishing emergency arrangements, e.g. ensuring suitable fire extinguishing media is available.

5. Personal protective equipment (PPE)

The last line of defence in the hierarchy. It is used when the measures above are deemed insufficient to control the risk. PPE for hot work may include the following:

Fire retardant coveralls or boilersuits.

Heat-resistant gloves.

FFP3 respirators.

Welding helmets or face shields.

Recap

The principles of prevention from MHSWR 1999 guide effective health and safety measures.

Health and safety policies are a legal requirement under The HSW Act 1974.

Prioritise eliminating risks by changing work methods.

Control risks at their source when possible.

Consult workers for input on control measures.

Leverage technology to enhance safety.

Develop and document a Safe System of Work (SSOW).

Use collective control measures over individual ones.

Provide adequate information, instruction, and training.

Prioritise health and safety to cultivate a positive culture.

Follow the hierarchy of controls: 1. Elimination, 2. Substitution, 3. Engineering Controls, 4. Administrative Controls, 5. PPE.

Cited Resources

L21 (MHSWR 1999): https://www.hseni.gov.uk/sites/hseni.gov.uk/files/publications/%5Bcurrent-domain%3Amachine-name%5D/l21-management-of-health-and-safety-at-work_0.pdf

HSW Act 1974: https://www.legislation.gov.uk/ukpga/1974/37/contents